krupp hardness test|dynamic hardness testing definition : manufacturers Standard tests such as tensile tests, bending tests, end quench tests, notched-bar impact-bending tests, hole expansion capacity and hardness tests according to the current standards complete the range of mechanical-technological materials testing services Explore our customizable autoclave labels for reliability and compliance in sterilization proce.

{plog:ftitle_list}

Hand-held Labeling Systems with 1150 labels per roll -Our Hand-held Labeling System has been designed specifically with Central Sterile in mind for the labeling of any items that you need to .

wantai elisa kit

Standard tests such as tensile tests, bending tests, end quench tests, notched-bar impact-bending tests, hole expansion capacity and hardness tests according to the current standards complete the range of mechanical-technological materials testing servicesThe test provides numerical results to quantify the hardness of a material, which is expressed .

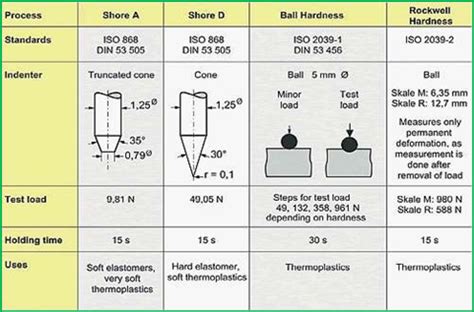

Standard tests such as tensile tests, bending tests, end quench tests, notched-bar impact-bending tests, hole expansion capacity and hardness tests according to the current standards complete the range of mechanical-technological materials testing servicesThe test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten . Toughness is a measure of how much resistance a steel has to fracturing. In the context of a knife this would be chipped edges or broken knives. Edge retention is the ability of . Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality control of a manufacturing or hardening process.

west nile virus elisa kit

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.It’s a low-end high carbon martensitic stainless steel, made by the German company Thyssen- Krupp, it’s very known in the knife industry, especially for in the Pharmaceutical knives and . The Knoop hardness test is a microhardness test designed for brittle materials like ceramics and glass, as well as for small or thin metal sections. It uses an elongated diamond . Rockwell hardness does not equate to a better knife all the time. You could have the same steel for two knives and both be Rockwell 60hrc but one could be far more refined. Just look for example at Busse knives. Much better grain structure without increasing hrc.

The Knoop hardness test / kəˈnuːp / is a microhardness test – a test for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes.The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number (HV) or Diamond Pyramid Hardness (DPH).

Standard tests such as tensile tests, bending tests, end quench tests, notched-bar impact-bending tests, hole expansion capacity and hardness tests according to the current standards complete the range of mechanical-technological materials testing servicesThe test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten . Toughness is a measure of how much resistance a steel has to fracturing. In the context of a knife this would be chipped edges or broken knives. Edge retention is the ability of . Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality control of a manufacturing or hardening process.

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.It’s a low-end high carbon martensitic stainless steel, made by the German company Thyssen- Krupp, it’s very known in the knife industry, especially for in the Pharmaceutical knives and .

The Knoop hardness test is a microhardness test designed for brittle materials like ceramics and glass, as well as for small or thin metal sections. It uses an elongated diamond .

Rockwell hardness does not equate to a better knife all the time. You could have the same steel for two knives and both be Rockwell 60hrc but one could be far more refined. Just look for example at Busse knives. Much better grain structure without increasing hrc.The Knoop hardness test / kəˈnuːp / is a microhardness test – a test for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes.

standards for hardness testing

how hardness testing works

hardness testing techniques

Rubber vulcanizing autoclaves enable rubber manufacturers to efficiently convert natural rubber and plastic into cured parts and products. These autoclaves can utilize live internal steam, a combination of live steam and hot .

krupp hardness test|dynamic hardness testing definition